Gravity Die Casting Dies

Gravity Die Casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Undercuts, and cavities can be incorporated into the component form with the use of sand cores. This process gives a better surface finish than sand casting as well as better mechanical properties, both due to rapid solidification.

Additionally, this process has a higher casting rate than aluminium sand casting, however, the metal moulds are a higher cost than sand. Advantages of this process include the possibility of low gas porosity, and fine grain sizes can be achieved.

Compared to sand casting, this process requires less finishing and fettling and gravity die casting tends to produce a higher quality product. The Gravity die casting production method is generally less cost effective in the manufacture of tooling compared with sand casting.

Materials Used in Pattern Making:

Cast Iron (Gray Iron or Ductile Iron)

- Properties: High compressive strength, good machinability, damping capacity, and wear resistance.

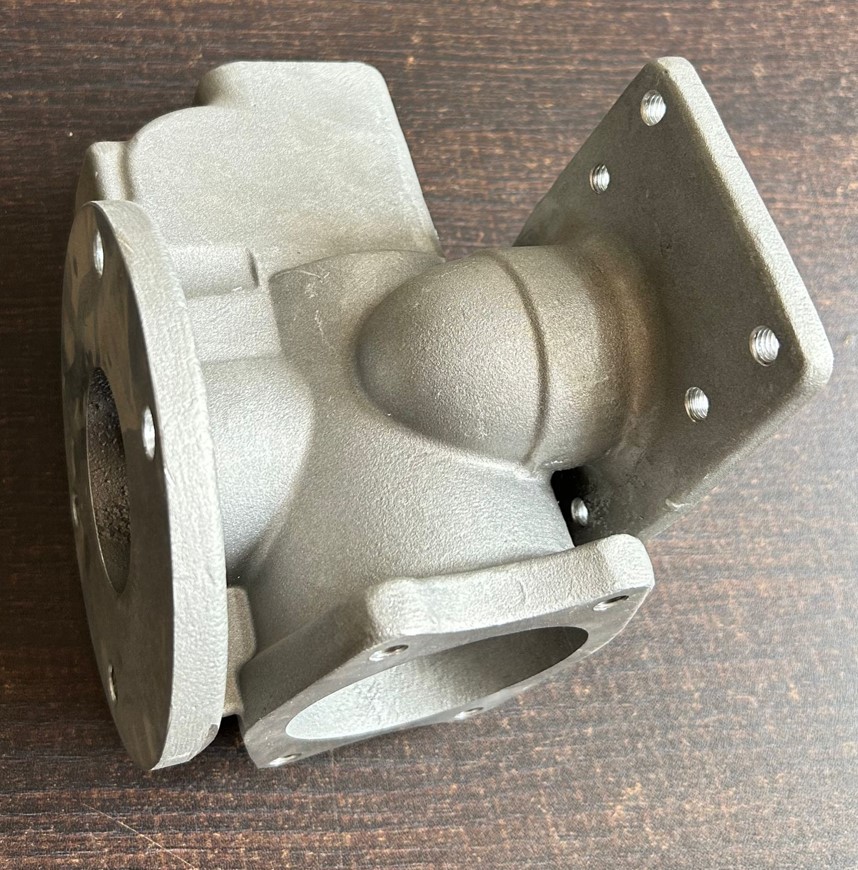

- Applications: Machine tool components (beds, bases, housings), automotive parts (engine blocks, brake discs, cylinder liners), pump housings, and hydraulic components.

EN8 (Carbon Steel)

- Properties: Moderate tensile strength, good machinability, and weldability.

- Applications: Gears, shafts, axles, crankshafts, and other mechanical components requiring moderate strength and toughness.

P20 (Tool Steel)

- Properties: Excellent machinability, good polishability, high wear resistance, and good toughness.

- Applications: Injection molds, die casting dies, extrusion dies, and other tooling applications requiring high wear resistance and dimensional stability.

H13 (Tool Steel)

- Properties: High hardness, excellent heat resistance, good toughness, and high hot hardness.

- Applications: Hot work tooling (die casting dies, forging dies, extrusion dies), injection molds for thermoplastics, and high-temperature applications requiring resistance to thermal fatigue and thermal shock.

GDC Making Process

- The process begins with understanding the casting requirements and component design.

- Engineers use CAD (Computer-Aided Design) software to create detailed 3D models of the GDC dies, considering factors like part geometry, tolerances, and draft angles.

- Design iterations may be necessary to optimize the die design for manufacturability and casting quality.

- Based on the design requirements and die casting process considerations, suitable materials for the dies are selected.

- Common materials include tool steels such as H13 or P20, which offer high hardness, wear resistance, and thermal conductivity.

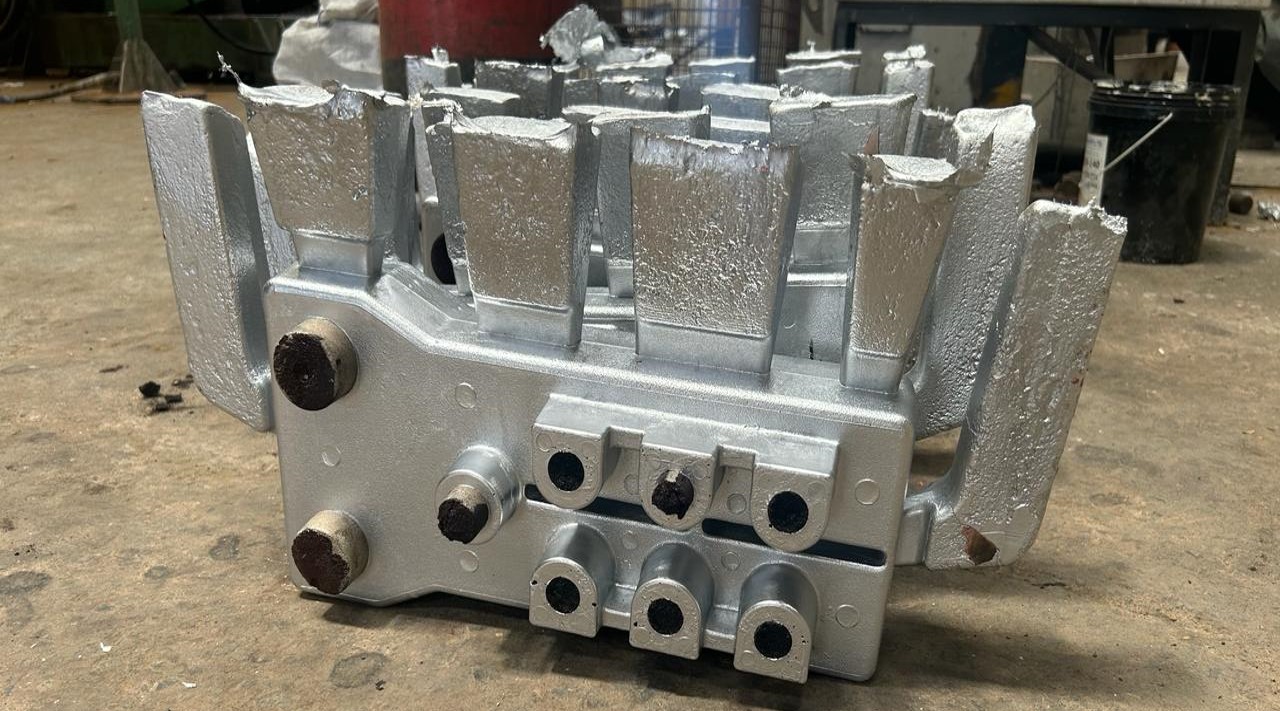

- The die block, which forms the main body of the die, is prepared for machining.

- This may involve rough machining the die block to remove excess material and prepare it for detailed machining operations.

- Precision machining techniques such as milling, drilling, and grinding are used to shape the die block into the final die geometry.

- CNC machining centers are often used to ensure high accuracy and repeatability in the machining process.

- The die may undergo additional finishing operations to achieve the desired surface finish and dimensional accuracy.

- Surface grinding, polishing, and coating applications may be performed to ensure smooth surfaces and optimal casting quality.

Assembly:

- If the die comprises multiple components, such as cores, slides, or inserts, these components are assembled into the final die assembly.

- Precision assembly techniques are employed to ensure proper alignment and functionality of all die components.

- The completed GDC die undergoes thorough testing and inspection to verify dimensional accuracy, fit, and functionality.

- Quality control measures are implemented to ensure that the die meets client specifications and industry standards.

- Documentation of die specifications, including materials, dimensions, and manufacturing processes, is prepared.

- Reports detailing quality control measures, inspection results, and compliance with client requirements are generated.

- Prototyping may be performed to produce prototype dies for design validation and testing.

- Iterative design and prototyping may be employed to refine die designs based on feedback and testing results.

- Technical support and consultation are provided throughout the GDC die manufacturing process.

- Collaboration with clients helps address specific needs, optimize designs, and ensure successful casting outcomes.