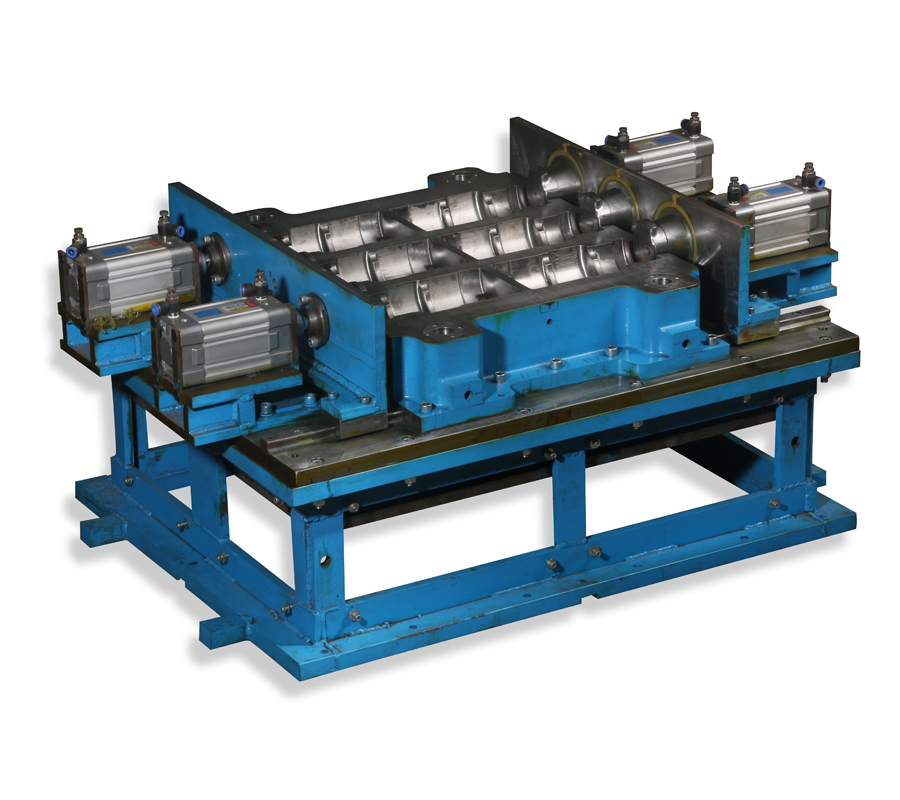

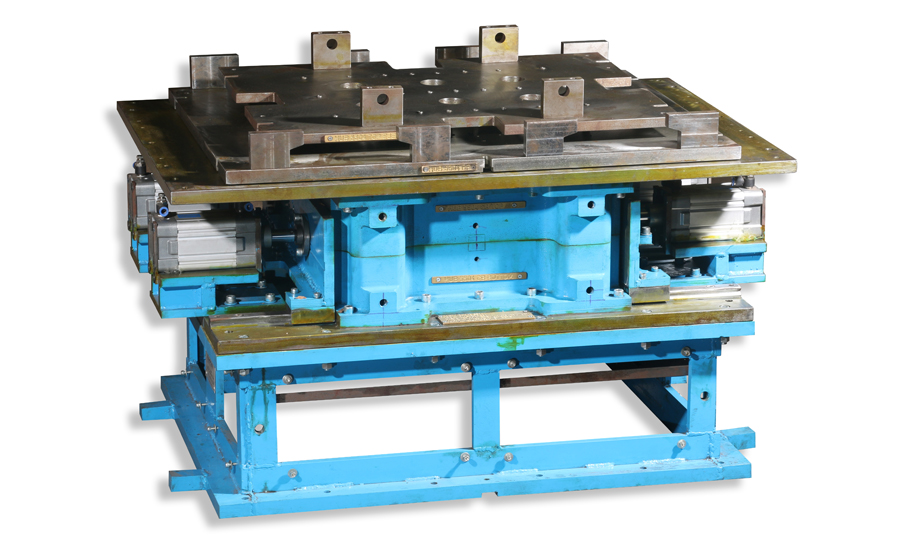

Core Boxes

Core boxes play a critical role in the casting process by shaping sand cores, which are inserted into molds to create internal features in metal castings. They come in various types, including split core boxes, matchplate core boxes, and ganged core boxes, each suited to different casting requirements and production volumes.

Core boxes are typically made from materials like cast iron, aluminum, or steel, chosen for their durability, machinability, and thermal properties. They are essential tools for achieving accurate and complex geometries in metal castings across industries such as automotive, aerospace, and manufacturing.

Core Box Materials:

Aluminium

- Aluminium core boxes are crafted from high-quality aluminium alloys known for their lightweight properties, corrosion resistance, and machinability. These core boxes are perfect for applications requiring rapid prototyping, low-volume production runs, or weight-sensitive components, providing versatility and efficiency in casting processes.

Cast Iron

- Cast iron core boxes offer exceptional durability, with high resistance to wear and deformation even under repeated use. Cast iron is relatively easy to machine, allowing for the creation of precise and intricate core box designs. Cast iron maintains its shape and dimensions well over time, ensuring consistency in the core box geometry. Cast iron has moderate thermal conductivity, which helps in efficient cooling of the core box during casting operations.

P20 Steel

- Known for its excellent machinability and polystability, P20 steel is a low-alloy tool steel that offers exceptional toughness and wear resistance. Our P20 steel core boxes are ideal for applications requiring intricate geometries and precise details, ensuring superior casting quality and reliability.

EN8 Steel

- With its excellent tensile strength and hardness properties, EN8 steel is a medium carbon steel that is highly durable and resistant to mechanical wear. Our EN8 steel core boxes are perfect for heavy-duty applications where strength and reliability are paramount, delivering consistent performance in challenging casting environments.

H13 Steel

- Renowned for its exceptional heat resistance and thermal conductivity, H13 steel is a hot-work tool steel that maintains hardness and dimensional stability at elevated temperatures. Our H13 steel core boxes are designed for high-temperature casting processes, offering superior performance and longevity in demanding applications such as aluminum casting and high-pressure die casting.

Manufacturing Process of Core Boxes:

- Initial Consultation: The process begins with an initial consultation between the client and our design engineers to understand the specific requirements and objectives of the project.

- CAD Modeling: Our experienced design team utilizes Computer-Aided Design (CAD) software to create detailed 3D models of the core box, incorporating the desired dimensions, features, and internal structures.

- Prototype Development: Upon approval of the CAD model, we proceed to develop a prototype of the core box using rapid prototyping techniques such as 3D printing or CNC machining. This allows for testing and validation of the design before full-scale production.

- Material Selection: Depending on the specific requirements of the project, the appropriate material for the core box is selected. This may include steel, aluminium materials.

- Machining or Casting: The selected material is then processed through machining, casting, or welding techniques to form the core box. CNC machining is often used for steel and aluminium core boxes to achieve precise dimensions and intricate geometries, while casting may be employed for resin-based materials.

- Surface Treatment: the core box undergoes surface treatment processes such as grinding, polishing, or coating to achieve the desired surface finish and dimensional accuracy.

- Assembly of Components: If the core box consists of multiple components or sections, they are assembled together to form the complete core box assembly. This may involve welding, bolting, or other joining techniques.

- Quality Control Checks: Throughout the manufacturing process, quality control checks are conducted to ensure that the core box meets the specified tolerances and quality standards.

- Final Inspection: Before shipment, the completed core box undergoes a final inspection to verify dimensional accuracy, surface finish, and overall quality.

- Packaging: The core box is carefully packaged to prevent damage during transit, ensuring that it arrives at the customer’s facility in optimal condition.

- Delivery: We work closely with reliable logistics partners to ensure timely delivery of the core box to the customer’s location, whether it’s a local facility or an international destination.