CNC Machining

- Utilization of CNC (Computer Numerical Control) vertical machining centers to perform various machining operations on workpieces.

- Capabilities include milling, drilling, tapping, boring, and threading operations.

Precision Machining

- High-precision machining of components to achieve tight tolerances, fine surface finishes, and intricate geometries.

- Utilization of advanced machining techniques and cutting tools to ensure accuracy and repeatability.

3D Machining

- Machining of complex 3D geometries, contours, and surfaces on workpieces using multi-axis CNC machining capabilities.

- 3D profiling, sculpting, and engraving operations to create intricate features and textures.

Prototype Machining

- Rapid prototyping services to produce prototype components for design validation, testing, and iteration.

- Quick turnaround times and flexibility to accommodate design changes and iterations during the prototyping phase.

Production Machining

- High-volume production machining of components for various industries, including automotive, aerospace, electronics, and consumer goods.

- Optimization of machining processes for efficiency, productivity, and cost-effectiveness.

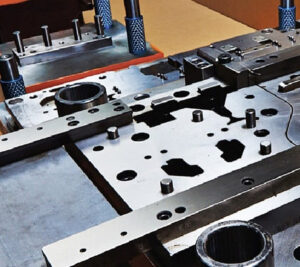

Tool and Die Machining

- Machining of tooling components, dies, molds, and fixtures used in manufacturing processes such as die casting, injection molding, and stamping.

- Precision machining of tool steel, carbide, and other materials to achieve long-lasting and durable tooling solutions.

Secondary Machining Operations

- Secondary machining operations such as deburring, chamfering, countersinking, and tapping to prepare components for assembly or finishing.

- Integration of secondary operations into the machining process to streamline production and reduce lead times.

Material Expertise

- Machining of a wide range of materials

- Selection of cutting tools, machining parameters, and coolant strategies optimized for specific materials and applications.

Quality Assurance

- Inspection and quality control measures to ensure dimensional accuracy, surface finish, and adherence to specifications.

- Utilization of metrology equipment, CMM (Coordinate Measuring Machine), and other inspection tools for accurate measurement and validation.

VMC works encompass a broad range of machining services aimed at producing precision components for various industries, from prototypes to high-volume production runs.