Die Design

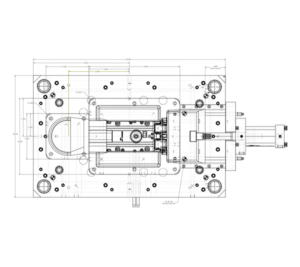

- Designing of mould, patterns, core box for casting process.

- Creating 2D and 3D CAD models of the die based on component specifications.

- Optimizing the die design for manufacturability, including considerations for part geometry, material flow, cooling channels, and gating systems.

- Conducting simulations and analyses to predict and optimize the filling and solidification of molten metal within the die cavity.

Component Design

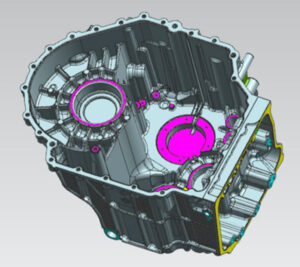

- Designing the component to be cast using gravity die casting.

- Creating 2D and 3D CAD models of the component based on customer requirements and specifications.

- Optimizing the component design for casting, including draft angles, fillets, and other features to facilitate the casting process and ensure part quality.

Tooling Design

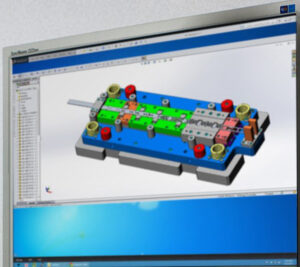

- Designing the tooling required for the gravity die casting process, including cores, slides, inserts, and gating systems.

- Creating 2D and 3D CAD models of the tooling components, ensuring proper fit, alignment, and functionality within the die assembly.

- Optimizing the tooling design for ease of assembly, disassembly, and maintenance.

Prototype Design and Development

- Designing prototypes of components or tooling for testing, validation, and iteration.

- Creating rapid prototypes using additive manufacturing (e.g., 3D printing) or traditional machining methods.

- Iteratively refining prototype designs based on feedback from testing and validation.

Simulation and Analysis

- Conducting simulations and analyses to predict and optimize the performance of die casting processes.

- Using software tools to simulate filling, solidification, cooling, and other aspects of the casting process to identify potential issues and optimize process parameters.

Design for Manufacturability (DFM) and Design for Assembly (DFA)

- Applying principles of DFM and DFA to optimize component and tooling designs for ease of manufacturing and assembly.

- Identifying and addressing potential manufacturing constraints, such as material selection, machining capabilities, and dimensional tolerances.

Value Engineering

- Analyzing component and tooling designs to identify opportunities for cost reduction, material savings, and process optimization.

- Recommending design modifications or alternatives to improve efficiency, performance, and cost-effectiveness.

These design services aim to support clients in optimizing the design of components, tooling, and processes for gravity die casting, ultimately enabling efficient, cost-effective, and high-quality production of cast components.